You can turn any clay body into paper clay. It's very easy.

Why would you want to do this instead of buying it ready made?

Well, the most important reason for me is that I can control the amount of paper I add to each batch. I would add much less paper to a piece I was going to carve than I would to a large wall hanging piece. The reasons? Carving tools can sometimes cause the paper fibers to drag or smear. For the wall hanging, I’m looking for less weight. I also keep a small amount of paper infused slip around for fixing greenware or bisque flaws.

Remember that paper clay is just paper fibers in clay. The fibers take up space, so they make the final piece lighter. The nature of the paper fibers make the unfired pieces stronger. BUT … after the bisque firing, you are simply dealing with a more porous version of your original clay. The paper is gone … burnt away in the early stages of firing.

If I were planning to throw paper clay I would probably buy the pre blended clay as it has a buttery smooth consistency that I have not been able to achieve in my own studio.

To make paper clay, buy the cheapest, one-ply toilet paper, unroll it and soak it overnight in a bucket of hot water. I make several batches using between 1/2 a roll to 1 1/2 rolls per 25 lb. bag of wet clay..

The amount of paper used is dictated by the end use of the clay. You might want more paper for strength if you are making large forms or less paper if you will be carving designs into the clay.

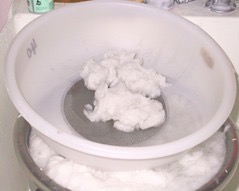

I use my regular glaze sieves to strain most of the water out of the pulp. I like to leave the pulp wet but not drippy.

Then I mix in the wet clay. My mixer is a pre-owned Hobart A120T and is 1/2 hp. You can sometimes find a deal on them at used restaurant equipment stores or from ads.

You could also use an old blender, an immersion blender or hand mixers. Keep them strictly for studio use.

Two other ways to mix are to dry the bagged clay, re-hydrate it and mix in pulp or to mix this pulp with dry clay using a drill mixer.

I add the pulp first, then add half of the wet clay. I leave it mixing for about 10 minutes or until it has become a smooth pulp. Then, I add the rest of the bag of clay in small pieces and let it mix until smooth.

As it is mixing, I put old newspapers down on the floor and cover them with an old bed sheet. I scoop the blended clay onto the sheet and let it dry until it is the consistency I like to work with. When ready, I seal it in plastic bags.

***A Note here on ageing of paper clay.

Yes, you will get black fungus and odor from old paper clay as the paper fibers dissolve. Some people add a tablespoon of bleach to the wet clay but others find this very irritating to their skin when they try to work with the clay.

A good idea for those who always want paper clay on hand is to flatten the paper clay into sheets and let it dry. It is quick and easy to add water whenever you need some.

It is also a great idea to keep some fiber in water in a jar. Any time you need to add a bit of paper to a slip to make minor repairs you have some ready to go. You need to add a bit of bleach to this jar as it will blacken and stink if you don’t.

For more options and information on coloring clay, look at the WORKSHOP pages of my site to find a class near you. If there isn't one, consider recommending my workshops to an Arts Center in your area.